What is the ash content of wood pellets?

To buy wood pellets for heating purpose, ash content is the first concern. High ash pellets can clinker and slag up the pellet furnace and require more cleaning work.

Traditionally, the quality of wood pellets are classified according to their ash residues.

- Premium wood pellets have the ash content less than 1%;

- Standard wood pellets have ash content between 1% and 2%;

- Industrial wood pellets have ash content over 3%.

The first 2 grades can be applied for commercial or residential purpose, with no harm to the boilers. But the last type is only sold for industrial application.

ENplus certification standard

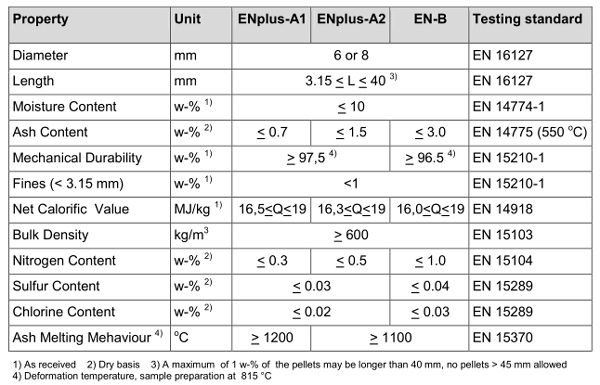

According to the standard of ENplus certification, wood pellets can be classified into 3 classes according to their ash content. They are divided into A1, A2, and B.

- The ash content of ENplus A1 level is less than 0.7%.

- The ash content of ENplus A2 level is lower than 1.5%.

- The ash content for ENplus B level is less than 3%.

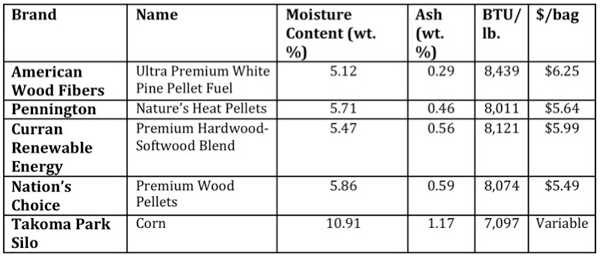

An American NPO—Alliance for Green Heat has carried out a test on 4 popular brands of wood pellets, including American Wood Fibers, Pennington, Curran Renewable Energy, Nation’s Choice , and Takoma Park Silo corn. Their ash content was relatively similar, ranging from 0.3-0.6%, which is lower than the ENplus A1 standard of 0.7%.

Ash fusion behaviour

Another indicator of ENplus A1 standard is ash fusion behaviour—the temperatures at which the ash begins to deform. Higher ash fusion temperature means less clinker and slag, higher efficiency, and less cleaning work.

The ENplus A1 specifications require the deformation temperature no less than 1200℃. The ENplus A2 and EN-B requires the temperature more than 1100 ℃. Both of them are higher than the temperature in pellet boilers, which can reduce the slag and clinker in burning.

There are other factors that affect the slagging in furnace:

- Dust and impurities may cause the ash to melt even though the furnace doesn’t reach the deformation temperature.

- The materials and condition of boiler also influence the combustion effect and clinker quantity of wood pellets.

- Operation also makes difference. If you often fill the ash-hopper too full and prevent the ash from escaping, it is adverse to full combustion and generates more smoke.

- We cannot completely eradicate clinker and slag in burning, so regularly cleaning the boiler is necessary.

How to deal with ash residue

The ash residue of wood pellets is mainly composed of minerals and carbons, you can spread it on your farm or garden as a fertilizer. Don't put too much ash in one place, or it would harm crops like overfertilization. We recommend you to collect them in a container after cooled.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!