other machines

Making biomass pellets contains the following necessary processes: crushing, drying, pelletizing, vibrating, cooling and packing.

Crushing: Wood debaker, wood chipper and hammer mill are used for crushing raw materials into small powders for making biomass pellets.

Drying: Rotary dryer is used for drying the crushed raw materials to ensure they have proper moisture content for the next step pelletizing.

Pelletizing: Pellet mill is used to make pellets from raw materials transported by rotary dryer. Usually, ring die pellet mill (also called industrial pellet mill) is used in pellets production line.

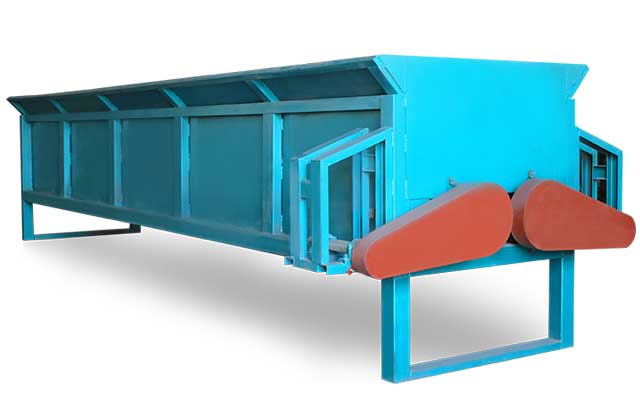

Vibrating:Vibrating screen is used to seperate the good-shaped pellets from their debris. In this process, the final pellets can also be cooled down a little. However, for large scale production of pellets, pellet cooler is strongly suggested.

Cooling: Pellet cooler is specially designed to cool pellets down for later being packed.

Packing: Pellets packing machine is used to pake pellelts into bags for later storage and transportion.

GEMCO provides all the necessory equipment for making pellets apart from pellet mills. The accessory machinery mainly includes: wood debaker, wood chipper, hammer mill, rotary dryer, vibrating screen, pellet cooler, and pellets packing machine, etc (shown as the following pictures).

GEMCO is able to establish your complete pellets making line according to your own needs and requirements. If you need any single equipment related to making pellets, we are your reliable supplier. Contact us now and you’ll find what you want!

Pellet Packing Machine Automatically Weighs, Packages Pellets

Pellet Packing Machine Automatically Weighs, Packages Pellets

GEMCO pellet packaging machine is composed of weighting, conveying and packing systems and intelligent controller for bagging pellets....

Read More Pellet Sifter | Pellet Vibrating Sieve | Wood Pellet Screener

Pellet Sifter | Pellet Vibrating Sieve | Wood Pellet Screener

Wood pellet vibrating sifter is widely used in pellets making lines to separate qualified pellets with good shapes from their debris before bagging them....

Read More Pellet Cooler | Counterflow Cooling Machine for Pellets

Pellet Cooler | Counterflow Cooling Machine for Pellets

GEMCO counterflow pellet cooler efficiently cools pellets of various length and diameters, thus reducing cracking pellets and making later packing pellets easy....

Read More Pellet Rotary Dryer for Sale | Drum Dryer in Wood Pellet Line

Pellet Rotary Dryer for Sale | Drum Dryer in Wood Pellet Line

Pellet rotary dryer is used to reduce or minimize the water moisture content of raw material for making pellets. GEMCO rotary dryer is your first choice. ...

Read More Wood Chipper Shreds Wood Effectively to Meet Your Needs

Wood Chipper Shreds Wood Effectively to Meet Your Needs

GEMCO wood chipper is widely used to pulverize wood logs, branches and planks into small wood chips. Wood chips' length can be adjusted based on your needs....

Read More Hammer Mill | GEMCO Hammer Milling Grinder | Wood Crusher

Hammer Mill | GEMCO Hammer Milling Grinder | Wood Crusher

GEMCO hammer mill with both small and large capacities crushes biomass materials effectively. It's mainly used in crushing raw material for later pelletizing. ...

Read More Wood Debarker for Sale, Log Debarking Machine, Rotary Debaker

Wood Debarker for Sale, Log Debarking Machine, Rotary Debaker

GEMCO wood debarker debarks wood logs effectively and thoroughly. It is high-quality at the most competitive price and enjoys good reputation worldwide....

Read More- Total 1 Page7 Records