industrial sawdust pellet mill

Industrial sawdust pellet mill is widely used in sawdust pellets factory and large scale pellets making line. It is a ring die pellet mill. Apart from sawdust, this ring die pellets making machine is able to make pellets from other biomass materials, such as: wood chips, wood shavings, branches, rich husks, corn stalks, peanut shell, bagasse, switch grass, agricultural residual and forest wastes.Pictures of Industrial Sawdust Pellet Mill

Technical Data of Industrial Sawdust Pellet Mill

| Model | Power(kw) | Packing Size (mm) | Net Weight (kg) | Capacity (ton/h) Sawdust/Stalks | Inner Diameter of Ring Die (mm) | |

|---|---|---|---|---|---|---|

| BPM35 | Main Motor | 60(30*2) | 2150*1950*1900 | 2200 | 0.5~0.8 | 350 |

| Feeding Machine | 0.75 | |||||

| Forced Feeding Machine | 0.75 | |||||

| BPM 40 | Main Motor | 90(45*2) | 2150*1950*1900 | 2200 | 1~1.5 | 400 |

| Feeding Machine | 1.5 | |||||

| Forced Feeding Machine | 1.1 | |||||

| BPM 45 | Main Motor | 110(55*2) | 2150*1950*1900 | 2200 | 1.5~2 | 450 |

| Feeding Machine | 1.5 | |||||

| Forced Feeding Machine | 1.5 | |||||

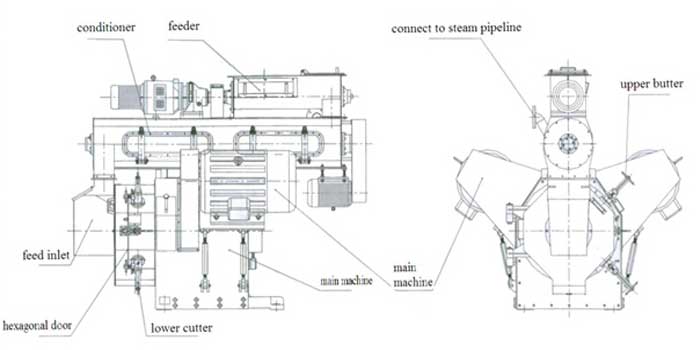

Structure of Industrial Sawdust Pellet Mill

This ring die sawdust pellet mill for industrial use adopts double belt driven system. Its motor is compatible with 3 phases, 380 volts and 50 Hz electricity. The ring die and the rollers are durable for about 1000 tons for stainless steel. Below is the picture of industrial sawdust pellet mill.

The sawdust ring die pellet mill’s cooling system is able to work continuously more than 8 hours. It is mainly used to cool down the inside temperature of pelletizing chamber and ensures that the pellet machine works stably and continuously. What’s more, the cooling system protects the motor and other electrical parts.

Advantages of Industrial Sawdust Pellet Mill

This ring die sawdust pellet mill solves the difficulty in granulating biomass crude fibers and poor effect. The pellet machine’s main drive adopts a high efficient belt to achieve refueling without stopping. Its cooling system is added to the granulating room and the circular mould adopts a quick detachable anchor ear type, which enables it easy to load and unload. Besides, frequency control of motor speed is adopted to ensure uniform feeding. What’s more, high-quality moulds are customized according to the characteristics of clients’ raw materials to prolong the life-extension of the equipment and reduce cost per ton. The molded pellet fuel is bright and clean in appearance, and has few cracks, high density and uniform length.

This ring die pellet mill adopts one-stop oil adding system. When the sawdust pellet mil is working, there is no need to stop the machine to add oil. Therefore, it can prolong the service time of the ring die and the rollers.

As this industrial sawdust pelletizer is belt-driven, so when working, the noise is very low. Meanwhile, maintenance is easy.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!