Requirement on raw materials for making pellets

Wood pellets, also known as biomass pellets, are made of sawdust, wood shaving, bark, twigs, wood dust, and waste wood in wood processing and wood-based panel processing. Besides, crop straws and other combustible biomass materials are also important sources. With regard to different raw materials, the calorific value and burning rate are different.

The combustion efficiency of wood pellets is over 80%, higher than the 60% of raw coals. What’s more, wood pellets fuel has less SO2, NOx, and dust emission. They are widely applied in furnace, heating stove, cook range and barbecue grill.

To achieve the best pelletizing effects, we need to control the size and moisture content of raw materials, or mix different materials together. The treatment of materials can reduce the wastage of the pellet press and improve the forming rate. The followings are requirement on raw materials for making wood pellets.

Moisture content

Wood pellets production has strict requirement on the water content of raw materials. No matter what kind of raw materials, the water content should be between 14% and 20%. Dry materials are not easy to form, while over-high moisture will make the pellets loose. You may need a dryer machine to keep the water content within a required level.

The size of raw materials

All biomass materials are required to be crushed before fed into the pellet press. For this process, you need a wood hammer mill or wood pulverizer. The size of crushed materials are determined by the size of pellets you want to make, and the hole sizes of pellet mill dies. Both oversized or undersized materials would influence the production capacity, or even block the machine.

Adhesion force of raw materials

Raw materials are supposed to bond together by themselves. If they don't have certain adhesive force, they can’t take shape in the pellet press or get loose and cracked easily. So, if you want to make pellets from raw materials with little adhesive force, you can mix them with other materials or binders. Sometimes people use fermented materials to improve their adhesive force.

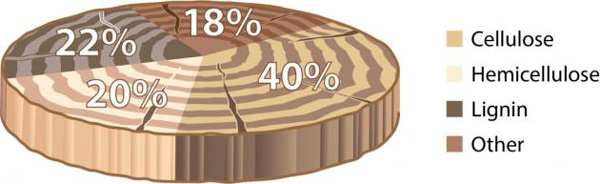

No binders are needed

Generally, you don't have to add any binders to make wood pellets. Because sawdust is a kind of high-fiber material. The lignin can melt under high temperature in the pellet press and play the role of binder. The pellet press can generate high pressure on the raw materials and mold them into hard solid pellets.

Mixed different materials

It is common to mix different kinds of materials together in pellet production. Sawdust pellets can be made of wood shaving, powders and scrapes of redwood and poplar. Broadly speaking, crop straw, peanut shells, rice husks are all suitable for making wood pellets, or rather straw pellets.

Raw materials mildew

If there mildew in the raw materials, the color would turn black. Some of the cellulose would get broken down by the microorganisms, and become unqualified for making pellets. If you decide to use mildewed materials, we recommend you to add more than 50% fresh sawdust materials, or they are unable to be successfully pelletized.

Requirements on specific materials

Fine sawdust

Sawdust produced by belt saws are an excellent material for making wood pellets. Because they represent the best size and adhesion force. Wood pellets made by sawdust features high hardness and smooth surface. Meanwhile, pellets presses fed with sawdust materials boasts stable production and low energy consumption.

Wood shavings

The large size of wood shavings makes them uneasy to get into the pellet mills. They are likely to block the pellet press and influence the production. Usually, we need to crush them into small size for pelletizing. In terms of small wood shavings, you can mix 30% of them with 70% sawdust.

Wood dusts

Wood dusts are common in wood mills and furniture factory. They are too light to get into the pellet press. Also they are easy to block the pellet press and reduce the production. It is recommended to mix 50% wood dusts with 50% sawdust to achieve the best pelletizing effect.

Wood scraps

Wood scrapes are residues of wood panels and pieces. They must be pulverized before making pellets. The crushing fineness should reach that of sawdust. We recommend 4mm as the best size. The pellets made by crushed wood scraps features smooth surface and high hardness.

Fibrous materials

To make pellets from fibrous materials, the length should be under 5mm. If the fibers are too long, they are easy to block the feeding system, and cause the failure of feeding system. You can mix them with around 50% sawdust to prevent the blockage of feeding system. To avoid the system failure, you should inspect it regularly.

In addition, it’s important the maintain the pellet making equipment regularly. Inspect each part of the equipment, clean the ash and sawdust on it, and lubricate the gear and wearing regularly. If you have any question on the raw materials or pellet mill maintenance, or if you want to make pellets from wood waste and crop residues, welcome to contact us in the form below. Our service team will answer your question timely.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!