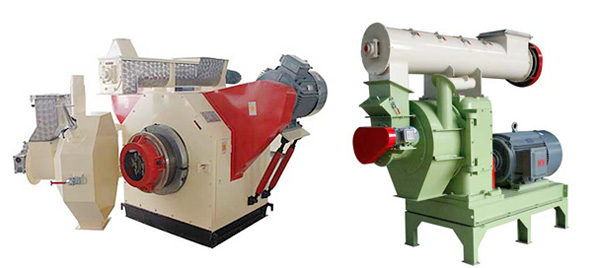

Differences between flat die and ring die pellet mill

According to working principle and production capacity, pellet production equipment can be classified into ring die pellet machine and flat die pellet machine. Flat die pellet mill appears at the beginning of 20th century, and ring die pellet mill appears in 1950s. Generally, the former one applies to small scale production, and the latter one are often used for large scale production.

Flat die pellet mill

Flat die pellet mills are usually driven by warm drive or gear drive, and the latter type is more efficient and stable. Besides, flat die pellet mill can be classified into R-type and D-type. R-type means the roller rotates and the flat die keeps still, which is directly driven by the engine. D-type means the flat die rotates and roller keeps still. Comparatively, R-type has higher productivity than D-type.

Working principle of flat die pellet mill

When you start the machine, the roller or die begin to rotates. They move relatively and form strong pressure and friction.

When you feed biomass materials through the hopper, they fall on the flat die and get compressed by the roller, then they are squeezed into the holes on flat die, where they are formed into solid cylindrical pellets.

Under the flat die there is a slicer cutting them into certain length. Then the pellets falls down and come out through the outlet.

Advantages of flat die pellet machine

- Flat die pellet mill is easier to clean.

- More simple structure. It is easy to replace the flat die and roller. You don’t need to spend much time for maintenance.

- With compact design, it features small volume and light weight. As they are portable, you can take them to anywhere for small scale production.

- High visibility of pellet production process. Through the hoper and observation port, you can easily find out if there is any problem in pelletizing and how to solve it.

- Flat die pellet mill has higher adaptability to defective materials, with less failure rate.

Weakness of flat die pellet mill

The working principle of flat die pellet mill gives rise to the uneven abrasion of the roller. When rollers are rolling on the surface of flat die, the inner and outer diameters are different. The outer part travels longer distance while the inner part is less. This means the roller can’t always be rotating. It may slide on the flat die and cause abrasion to the roller surface.

However, adoption of tapered roller can make up for this deficiency.

Ring die pellet machine

The compression part of ring die pellet mill is made up of a vertical ring die and a roller in it. The roller put pressure on the inner surface of ring die.

Advantages of ring die pellet machine

- Ring die pellet machine is more suitable for large quantity production. Because its roller and die has longer working life, and the unit energy consumption is comparatively low.

- There is no uneven abrasion taking place in ring die and roller, for the inner and outer diameter of roller is the same.

- The slide of roller in flat die pellet mill result in extra power consumption and more abrasion. But the slide also generate heat that improves the pelletizing effect. For this reason, all ring die pellet making machines are equipped with a tuner and a speed regulation device.

Weakness of ring die pellet mill

- Large volume and weight makes ring die pellet mill unsuitable for small scale production.

- To replace the roller and die can takes a lot of labor work. As the ring die is large and heavy, it requires an elevator to complete.

- It's more complicated to adjust the roller, staffs have to open up the compression cabin to get in. Some ring die pellet machine can be adjusted by remote control, but it takes extra cost.

- High cost is a distinct weakness of ring die pellet machine, which goes for both machine and spare parts.

- As the compression part is segregated by a door, you cannot figure out the problem by observing the compression process. The working process is invisible.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!