make bamboo pellets

Bamboo

Bamboos (subfamily Bambusoideae) are among the broad-leaved grasses (Poaceae) associated with forest habitats, but bamboos are the only major lineage of grasses to diversify in forests. There are (according to some classifications) between 1 050 and 1 070 different species of bamboo in the world, from the tiny Sasa to the subtropical giants.

Bamboo is a type of grass with a hard, round, fibrous, hollow stem. It is straight up and perennial evergreen, which means that it stays green year round. Bamboo grows quickly and can be harvested annually without depletion and deterioration of the soil.

Bamboo Distribution

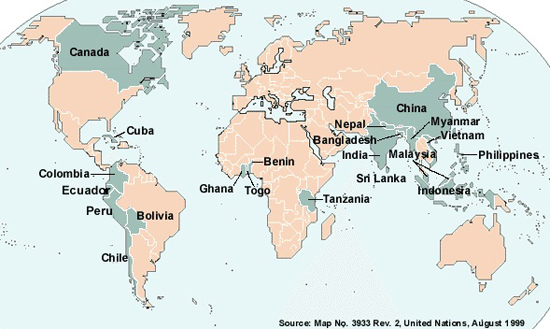

Bamboo has strong fertility and grows very fast. It can grow on marginal land, not suitable for agriculture or forestry, or as an agroforestry crop. Bamboos have a wide natural distribution, occurring from approximately 46° N latitude to approximately 47° S latitude and from sea level to as much as 4,300 meters (ca. 14,000 feet) in elevation in equatorial highlands. As a common forest resource, bamboo is especially widely distributed in Asia, America, and Africa.

Southeast Asia monsoon zone (southeastern China, southwestern China, Indochina and the Indian subcontinent) is the world's bamboo distribution center, the region has concentrated 80 percent of the world's bamboo species, 90% of the total bamboo forest area. America and South Africa also contain vast varieties of bamboo. In some of these countries it is related to the culture, the construction and the history. In Latin America, Mexico, Guatemala, Costa Rica, Nicaragua, Honduras, Colombia, Venezuela and Brazil, the Amazon Basin in South Tropic of Cancer is the area of bamboo distribution center. And the east coast of Madagascar is the center of Africa bamboo distribution.

Bamboo Usages

Bamboo has numerous usages, among which the most common are as follows:

Construction Material: Bamboo is an extremely hard substance, although it should be chemically treated to prevent insect infestation and rot. Bamboo grows rather quickly, sometimes growing up to 3 to 4 feet (0.9114 to 1.2192 meters) a day—it can grow in dense conditions, so it is considered one of the best renewable resources on our planet. Bamboo was used to create the earliest suspension bridges in China, and today, it is used in a variety of building projects. It has also been used to craft boats, zeppelins and airplanes.

Musical Instruments: Many musical instruments are made from bamboo or use bamboo as well. And the best example may be the reeds of the double reed family, which includes the oboe, English horn, bassoon and related instruments.

Food: Bamboo has a crisp texture and light, sweet flavor. Some animals that eat bamboos include pandas (especially in China), lemurs and chimpanzees. Bamboo shoots are often cooked as filler in Asian cuisine. While some kinds can be eaten raw, other varieties must be cooked to remove some toxic elements.

Household Utensils: It is very common to find furniture, dinnerware, sporting goods, jewelry, handbags and other containers comprised of bamboo.

Besides, bamboo is also widely used as medicine and weapons to block blows or to deliver them.

Bamboo has received increasing attention over the last two decades for its economic and environmental values. Nowadays, with the development of the new green energy, biomass fuel, bamboo becomes one of the economical green resources when compressed into bamboo pellets.

Bamboo Pellets

Bamboo pellets are made of bamboo stalks, bamboo leaves and recycling bamboo powders after production of other bamboo products, by crushing the bamboo into powder and pressing together into pellets with 6-12mm length. Bamboo pellets deliver extremely high BTU's and low ash content, and they are a reliable, cost-effective and environment-friendly source of energy for heating systems.

As clean bio-energy, bamboo pellets have better flow properties. Densification into pellets reduces material wastage and improves ease of transporting and storage. Bamboo Pellet’s Specification is as follows:

- Density: >1.22kg/m3

- Diameter: 6-8mm

- Length: 6-12mm

- Calorie: 4500-4800KCAL/KG (18.8-20MJ/kg)

- Moisture: standard 8.7%, 9.6%max

- Ash Content: standard 0.9%, 1.1%max

Kindly notice that moisture content and pellet size affects the physical and combustion properties of bamboo pellets. The effects of moisture content on bamboo pellet’s physical properties include length, diameter, pellet moisture content, unit density and bulk density. And some researches have proved that when moisture content is about 16% and pellet sizes mixed in the bamboo pellets manufacturing process id the optimum choice. On that condition, all properties of bamboo pellets could meet the requirement of Pellets Fuel Institute Standard Specification for Residential/Commercial Densified, and the gross calorific value of bamboo pellets could also meet the minimum requirement for making commercial pellets of DIN 51731 (>17500J/g), respectively. Bamboo pellets are the proposed new biomass solid fuel and had the potential to be development as commercial pellets.

Make Bamboo Pellets

The process of making bamboo pellets is just like the other biomass pellets, such as wood pellets, sawdust pellets, and rice husk pellets, etc. Bamboo pellets are usually made in large scale for industrial heating in areas where bamboo is a rich resource.

Bamboo Pellets & Bamboo Pellet Mill

Bamboo Pellets

Household Bamboo Pellet Mill

Industrial Bamboo Pellet Mill

The manufacturing process of bamboo pellets usually includes the following processes: crushing, drying, pelletizing, cooling, packaging.

- Sometimes, before crushing, you need to separate the bamboo materials like bamboo leaves and bamboo stalks from debris and dusts. Then crush the raw material into bamboo powders for making bamboo pellets.

- The drying process is to make sure that he crushed bamboo powders have proper moisture content. A rotary dryer is usually necessary in this step.

- The pelletizing is to compress the bamboo powders into pellets by bamboo pellet mill. Generally speaking, wood and sawdust pellet mills can also make pellets from bamboo as the hardness of wood and sawdust is higher. You can make bamboo pellets for your own use with GEMCO residential bamboo pellet press. Or if you want to invest in the bamboo pellets market, GEMCO industrial bamboo pellets making machine is a good choice for you to establish bamboo pellet production line.

- You will get quality bamboo pellets after the pelletizing process. However, the pellets have high temperature when they leave the bamboo pellet mill. For maintaining their quality and later storage, cooling is very necessary. Bamboo pellet cooler, also called bamboo pellets cooling machine is used to cool pellets' temperature down. As a professional bamboo pellet cooler manufacturer, GEMCO supplies quality bamboo pellets cooling machine for you.

- After all the processes above, you can package the bamboo pellets with bamboo pellets packaging machine.

If you want to invest in bamboo pellets business, we can help you analysis your targeted market, establish your desired bamboo pellet plant and solve all the problems you may encounter.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!