What are the types of hammer mill?

Hammer mill is a common equipment in wood processing factory and wood pellet plant. It serves to crush wood materials into powders so that they can be used to make wood pellet fuel and other wood products. It can process pines, poplar, cedar, bamboo, weed tree, and various fiber materials like rice straw, cotton stalk, twitch grass, etc. Hammer mill applies to materials whose diameter is 10-30mm, and reduce their size to 3-5mm.

Hammer mill is the most widely used wood crusher. It use high-speed rotating hammers to crush the wood materials. Hammer mill features simple structure, wide applicability, high product efficiency, and easy operation.

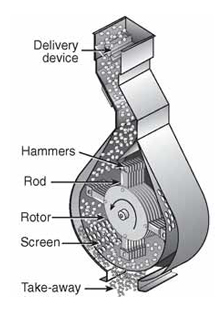

Structure of a hammer mill

A hammer mill is mainly composed of 3 parts, the feed hopper, the pulverizing room (includes rotator, hammers, screener, toothed plates), and the discharge part (includes wind blower, aggregate cylinder, dust bag).

The working principle of a hammer mill

First, you feed the wood materials into the feed hopper and they will fall into the pulverizing room. In the pulverizing room, the wood materials are beaten by the high-speed rotating hammer and bounce to the toothed plates, then they bounce back and repeat this process. Meanwhile, the materials are grinded between the hammers and screener. Under the beating, collision and friction of the hammers, toothed plates and screener, the wood materials are crushed into small particles until they are small enough to get through the screener.

Then, the crushed wood materials are pumped out through the screener by the blower. There is a wood powder collector (a aggregate cylinder or a dust bag)that separate the air from the final products. If the hammer mill isn’t equipped with a wind blower, the crushed materials will be expelled out by the airflow in the pulverizing room.

Types of wood hammer mill

According to the shape of screener, hammer mill can be classified into half-screen hammer mill, full-screen hammer mill, and screenless hammer mill. According to the size and production capacity, it can be classified into small hammer mill and large hammer mill.

Small hammer mill

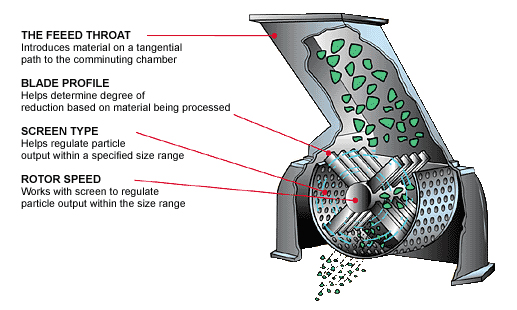

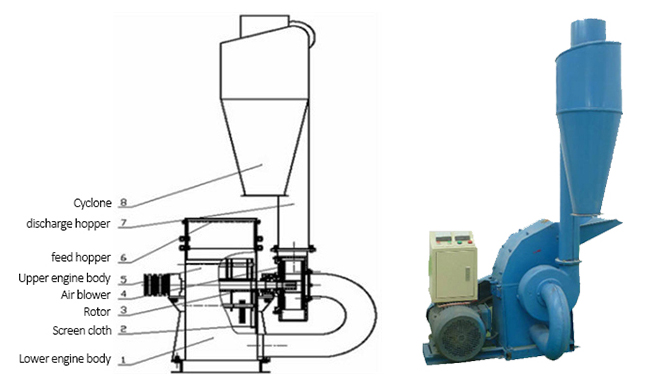

Small hammer mill is also called half-screen hammer mill, because the screen cloth is a semicircle covering the lower part of the rotor. The toothed plate is installed in the upper body. Raw materials are fed along the tangent line of the crushing chamber.

A hammer mill is composed of a feed hopper, discharge hopper, engine body, air blower, rotator fixed with hammers, screen cloth, cyclone, etc.

Small hammer mill is a general type. It adapt to different working conditions. It features small size, low cost and easy operation. Small hammer mills are usually applied in farm, small feed mill, small pellet production line, and wood processing plant.

Cyclone in small hammer mill

Small hammer mill is equipped with a cyclone. It serves to separate dusts with centrifugal force. When the mixed air and dust get into the cyclone through the portal at the top of the cyclone, they do centrifugal rotation along the inner side of the shell. As the dust and air are different in gravity, the dust and air slow down when they get into the cyclone. When the centrifugal force fade away, the dust is blocked in the cyclone and the air is expelled out. It adopt centrifugal force to separate dust. Both coarse and fine dusts can be collected, the gathering density is high.

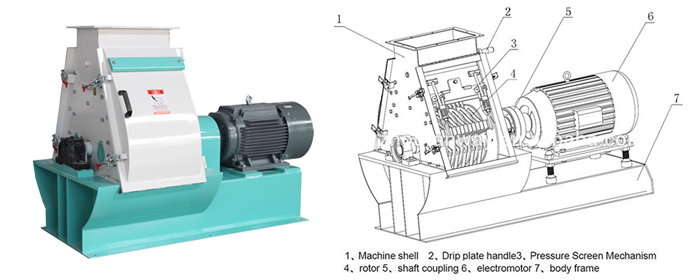

Large hammer mill

Large hammer mill is also called drop-shaped hammer mill. The electric motor and rotor are welded on the same steel plate base. They are directly connected by a pin coupling. With dynamic balance experiment, the rotor can rotate in both directions. The feed hopper is at the top of the hammer mill. You can equip it with a rotary feeder. The hammers are arranged symmetrically. The operation door is equipped with a interlock device to ensure it is closed during running.

How does a large hammer mill work

Raw materials are fed through the hopper at the top of the hammer mill. Under the guidance of the guide plate, they get into the crushing chamber. Under the beating of the hammers and the friction of the screener, the raw materials gradually get crushed. Under the centrifugal force and the suction of air blower, the crushed materials pass through the screener and are expelled out from the discharge port.

Structure of a large hammer mill

- Base: serve to connect and support all parts of the hammer mill. The crushed materials are discharged under the base.

- Rotor: composed of the main shaft, hammer frame plate, hinge pin and bearings. It is the working part of the hammer mill. The rotating speed is high. The rottor need dynamic balance experiment before the hinge pin and hammer plate are installed.

- Operation door: you need open the operation door when replacing the screener or hammers. The operation door has wheels at the bottom that allows you to push is aside during maintenance. The screener is fastened with a special hold-down mechanism. During the running of the hammer mill, the operation door is locked by a single-acting cylinder to ensure it can’t open.

- Upper cover: It has the feed hopper at the top and the base at the bottom. The screeners are installed on the inner sides of the upper cover. They form the pulverizing chamber with the rotor. This is where the raw materials are crushed.

- Feed guide device: let the raw materials get into the crushing chamber from the left or right side. The rotating direction of the motor and the guide plate should be the same. The feed plate is controlled by a DQK air cylinder, and the rotating direction of the motor is controlled by a travel switch.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!