Biomass pellet fuel application and pellet burning equipment

Biomass pellet fuel properties

Biomass is the worlds’ 4th largest energy, next only to oil, coal and gas. Biomass energy is both renewable and environmental friendly. To relieve pollution and CO2 emission, people pay more attention to the development and application of biomass fuel.

BMF (biomass molding fuel) is made from crop straw, sawdust and other materials. These materials are compressed under high temperature, high pressure of the biomass molding equipment. BMFs appear as bar, briquette and pellet. Among them, biomass pellets are the most prevalent for its high mobility and combustion rate.

The calorific density of BMF equals that of middle coals. Meanwhile, the NOx and SO2 emission of biomass fuel is much lower than coal, the CO2 emission is little, and the ash residue is low. Therefore, making biomass fuel into pellets can improve the utilization efficiency of the biomass materials. The world’s largest wood pellets consumers are Europe and America.

Biomass pellet fuel refers to the formed cylindrical solid fuel whose diameter is under 25mm. The densities are 1.2-1.4kg/m3. The volume is cut down by 75%-90% than the bulky materials, so pellets are convenient for transportation and storage. Uniform size and good flowability makes them qualified for automatic transmission and burning.

The volatiles in biomass pellet fuel are much higher than coal, usually between 60% and 70%. As a high-activity fuel, it is easier to ignite and burn. The carbon content is 35-42%, a number lower than coal, so its calorific value is lower than coal. The Nitrogen content is only 0.5%-3%, the sulphur content is only 0.1-0.5%, so the NOx emission is only 1/5 that of coals, and the SO2 emission is only 1/10 that of coals. Compared with bulky biomass materials, the combustion time increase remarkably. In conclusion, biomass pellet fuel are a kind a high-quality, clean and efficient fuel.

Different biomass pellet fuel properties

| raw material |

pellet density g/cm3 |

ash content % | volatile % |

gross calorific value kJ/kg |

|---|---|---|---|---|

| corn stalk | 1.30 | 5.07 | 72.22 | 13847 |

| rice husk | 1.39 | 13.23 | 63.22 | 15489 |

| pine leaves | 1.36 | 5.95 | 69.82 | 19529 |

| fruit shell | 1.37 | 4.53 | 65.70 | 17689 |

| sawdust | 1.37 | 3.33 | 72.31 | 17691 |

| fruit shell & sawdust | 1.34 | 5.04 | 67.40 | 16804 |

| pine leaves & sawdust | 1.35 | 4.84 | 72.52 | 19217 |

| pine leaves & fruit shell | 1.44 | 7.89 | 66.39 | 18161 |

The data is acquired by experiment. The pellet density is measure by buoyancy method.

The development of biomass pellet burning equipment

In the 1930s, many countries began the R&D of biomass molding technology. These technologies have been applied widely in business scope. These equipments includes flat die pellet mill, ring die pellet mill and briquette press.

In terms of the BMF burning equipment, it began in the 1950s when the first rod type fuel burning equipment come out. In the 1970s, wood pellet burning equipment appears in America. After that, many European countries such as Sweden, Finland and Denmark also developed pellet molding machine and burning equipment. And in 1980s, these equipment appears in Thailand, Philippines and other Asia countries.

Currently, the pellet burners has developed to maturity. They are widely applied in heat supply, drying and power generation. The application of biomass pellet burner start in the 1980s, but it didn’t get remarkable market share until the late 1990. Finally, they become popular in Sweden, Demark, Austria, Germany and other European countries. Thank to the normative manufacture process, the wood pellet burners feature reasonable technology, high degree of specialization, automation, high heating efficiency and little smoke emission.

The applications of biomass pellets burning equipment

Pellet stove for heating and cooking

In Europe and America, home-use biomass pellet fuel and pellet burners have been widely applied. Wood pellet fuel has become the preferred choice in many families. The efficiency of home heating stove can reach up to 80%. This number is more than 90% in the high-efficiency burner adopted by residential areas and schools.

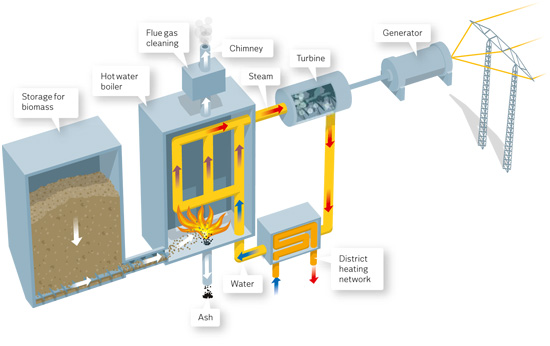

Biomass power generation equipment

The research of biomass power generation start in the 1970s. Biomass power generation technology can be classified into biomass direct burning, combustion of mixed biomass and coal, and biomass gasification. At present, biomass power generation technology and equipment has gotten mature in developed countries.

In Austria, they have build a regional electric supply station that use wood residues as fuel. In Demark, the straw burning power generator sets developed by BWE company has come into use in Demark, Spanish, Sweden and French for many years.

In America, the installed capacity of biomass power generators have achieved 16.3 GW in 2015, of which 70% adopts mixed biomass and coals as fuel. compared with directly burning or gasification, the combustion of mixed pellets and coal has more advantages of high technology maturity, high energy utilization, low equipment investment, and storage and transportation convenience. As indicated by foreign experience, biomass pellet fuel have huge potential for the large application scale and low cost.

Other industrial utilization

Another significant use of biomass pellet fuel is large-scale heating, drying in industry field. Nowadays, many developed countries like England, French and Italy adopt large-scale boiler to apply crop straws in heating and drying industries. They have achieved high-maturity technology and high-automatic production.

In conclusion, biomass pellet fuel can be applied for home heating, power generation and industrial production. The biomass application technology is increasingly mature in developed countries, and will be promoted to more developing areas in the future. The growing demand of wood pellet fuel is certain to boost the development of pellet machine and briquette press.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!