biomass energy in vietnam

Biomass Fuel in Vietnam

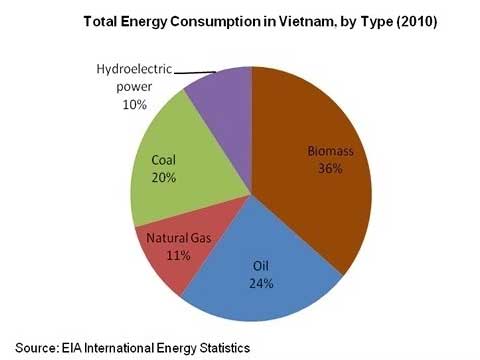

Biomass fuel as economical energy takes the lion share in the total energy consumption in Vietnam. Vietnam has large amount of biomass resources, and its primary biomass sources for energy production are crop residues and wood fuel.

The main biomass fuel resources are paddy straw (32.1% from the total potential), firewood fuel (30.3%), maize trash (18.5%), rice husk (6.6%) and bagasse (4.0%). Also available small amount of other biomass resources are cane trash (2.8%), cassava stem (2.6%), peanut shell (0.2%), coconut shell (0.1%) and coffee husk 0.5% (Table 3) (Tran 2011). All together agro-biomass residue potential was 72.7 million tons (69.6%) and the wood fuel was 31.7 million tons (30.4%).

From agricultural residues the most important are rice husk, rice straw, bagasse and maize trash. They cover about 57% of the total biomass resources and 93% of the agro-biomass potential in Vietnam. The main biomass resources are at Mekong River and Red River Delta regions. The main rice husk and rice straw producers are the Red river delta and the Mekong river delta regions. The biggest bagasse producers are the Mekong delta, the North central, the Central coast and the South-East regions. Maize is cultivated mainly on Central Highlands, North East, South East and North Central Coast regions.

The crop residues can be divided into agricultural by-products (rice straw, corn leaves and cobs etc.) and agro-industrial by-products (rice husk, bagasse, peanut shells, coffee husks etc.). The total main solid biomass fuel potential of Vietnam is about 104.4 million tons in 2010, corresponding to about 1 346 PJ (374 TWh) of energy production potential every year. ( 1 TWh is 3.6 PJ ).

| Type of biomass | Potential in 2010(wet)mill tons | Energy content(as received)kWh/kg (MJ/kg)> | Potential in 2010 (as received)TWh (PJ) | Share% (TWh) |

|---|---|---|---|---|

| Rice husk | 7.52 | 3.3 (11.9) | 24.8(89.3) | 6.6 |

| Rice straw | 37.57 | 3.2 (11.5) | 120.2 (432.8) | 32.1 |

| Bagasse | 7.20 | 1.8 (6.5) | 15.1 (54.4) | 4.0 |

| Cane trash | 2.40 | 4.2 (15.1) | 10.3 (37.2) | 2.8 |

| Maize trash | 15.00 | 4.6 (16.6) | 69.0 (248.4) | 18.5 |

| Cassava stem | 2.28 | 4.2 (15.1) | 9.6 (34.5) | 2.6 |

| Peanut shell | 0.18 | 5.1 (18.4) | 0.8 (3.0) | 0.2 |

| Coffee husk | 0.40 | 4.3 (15.5) | 1.7 (6.2) | 0.5 |

| Coconut shell | 0.14 | 4.4 (15.8) | 0.6 (2.2) | 0.1 |

| Firewood | 27.60 | 4.1 (14.8) | 113.2 (407.4) | 30.3 |

| Wood residues from sawmills | 4.08 | 2.1 (7.6) | 8.6 (30.8) | 2.3 |

| Total | 104.37 | 373.9 (1 346.2) | 100 |

- Rice husk, also called rice hull, is the outermost layer of the paddy grain, and it is separated from the brown rice in rice milling.

- Rice straw’s largest cultivation area is Mekong River Delta, which contributes 54 % of paddy straw and rice husk production in Vietnam. The residues of paddy harvesting are paddy straw and stubbles.

- Bagasse is the fibrous material that remains after sugarcane are crushed to extract their juice.

- Cane trash consists of leafy leftovers of the sugarcane harvest.

- Maize trash refers to the leaves and stalks of maize plants left in a field after harvest. Maize trash makes up about 2.5 times the yield of a maize. Maize husk refers to the leafy outer covering of an ear of maize as it grows on the plant. Corn cob is the core of an ear of maize, to which kernels are attached.

- Cassava stem

- Peanut shell: In 2010 the peanut production was about 0.6 million tons. With and average shell to peanut ratio of 0.3, the total peanut shell generated in 2010 was 0.18 million tons.

- Coffee husk is mainly from Robusta coffee. Vietnam now has 560 000 households growing coffee, generating steady jobs for over half a million people and offering millions of part time jobs during harvesting season.

- Coconut shell’s total production in Vietnam in 2010 was 0.14 million tons. The main cultivation area of coconut in Vietnam is the Mekong River Delta region. About 74% of coconut in Vietnam is cultivated in this area (Vinay chand associates 2011).

- Firewood is any wood-like material that is gathered and used for fuel in small fireplaces.

- Wood residues from sawmills are mainly sawdust and wood chips. Sawdust is a by-product of cutting timber with a saw, composed of fine particles of wood. Wood chips are also a by-product of forest industry. Wood chips are made from logs not suitable for further processing.

Biomass Fuel Properties

The calorific value of woody biomass is higher compared to the agricultural biomass. The calorific value of dry wood (Qnet,d) is about 5.3 kWh/kg (19.0 MJ/kg). From the agricultural biomass the calorific value (Qnet,d) of rice husk and straw is lower (12.6–14.6 MJ/kg) than the calorific value of the other agricultural biomass fuels like bagasse, coffee husk and coconut shell (15.5–17.8 MJ/kg). The main reason for lower calorific value of rice straw and rice husk is the higher ash content

(15–25%) compared to other agricultural biomass fuels (1–8.0%) (Table 2). The ash content wood biomass is low, 0.5–2.0%. The moisture content while using biomass as a fuel is 40–55wt-% with bagasse and wood fuels. With other biomass fuels it is between 10–20wt-%. That is why the calorific value of bagasse and wood fuels ‘as received’ (Qnet,as) is low being 2.1 kWh/kg (7.5 MJ/kg) compared to agricultural biomass fuels, 3.0–4.7 kWh/kg (10.8–16.9 MJ/kg).

With pelletizing it is possible to increase the calorific value of wet biomass fuels like wood and bagasse. In pelletizing process the biomass is dried up to 13wt-%. The calorific value of wood pellets ‘as received’ (Qnet,as) is 3.9–4.9 kWh/kg (14.0– 17.6 MJ/kg).

| Fuel type | Moisture content % on wet basis | Ash content % on dry matter weight | Qgr,d kWh/kg(MJ/kg) | Qnet,d8 kWh/kg(MJ/kg) | Qnet,ar kWh/kg(MJ/kg) | Bulk density, wet(kg/loose-m3) |

|---|---|---|---|---|---|---|

| Paddy straw | 12–22 | 15–25 | 4.3 (15.3) | 4.1 (14.6) |

3.0–3.5 (10.9–12.6) |

75 loose 100–180 bailed |

| Rice husk | 8–12 | 17–26 | 4.9 (17.5) |

3.5–3.7 (12.6–13.4) |

3.0–3.4 (10.8–12.1) |

75 loose 100–180 bailed |

| Bagasse | 50 | 1–4 | 4.4 (15.7) | 4.3 (15.5) | 2.1 (7.5) | 120 |

| Coconut shells | 10–20 | 4–5 |

4.6 (16.7) |

4.2–4.4 (12,9–14.8) |

||

| Coconut husks | 5-9 | 6 |

4.6 (16.7) |

4.2–4.4 (12,9–14.8) |

||

| Coffee husk | 10-12 | 1-4 | 4.5–5.1 (16.1–18.2) |

4.9 (17.8) |

4.3–4.4 (15.4–15.8) |

185–300 |

| Maize residues | 6-8 | 3-8 | 5.1 (18.2) | 4.6 (16.4) | ||

| Peanut shell | 9 | 5,7 |

5.1 (18,3) |

4.6(16.4) | ||

| Forest chips | 40-55 | 0.5-2.0 |

5.1-5.6 (18.5–20.0) |

1.9–3.1 (7.0–11.0) |

250–350 | |

| Sawdust | 50–55 | 0.4-1.1 |

5.2–5.3 (18.9–19.2) |

2.0–2.3 (7.2–8.4) |

250–300 | |

| Wood pellets | 8-10 | 0.3-0.5 |

4.4–5.3 (15.8–19.2) |

3.9–4.9 (14.0 -17.5) |

640–690 | |

| Firewood - Pine, spruceand birch | 20 | 1,2 | 5.1-5.(18.3-20.0) | 4.1(14.8) | 240–320 |

Biomass Energy in Vietnam

In Vietnam, lots of biomass is used as energy. Biomass is mainly used in households (76%), and the rest (24%) is used in small industrial boilers and CHP plants in sugar mills. The main energy consumption potential in Vietnam is in municipal and industrial co-generation power plants (CHP) in steam, heat and power generation. Here you should also consider one of the main problems of combined heat and power (CHP) plant if as an investor. The problem is the reliable delivery of biomass fuel all year round. The main reasons for this include: the seasonal production of biomass, many small, scattered biomass owners and undeveloped biomass production, collection and transport system.

As an important energy source in Vietnam, it is estimated that about 70% of rural population are relied on biomass energy as daily cooking fuel. Besides, biomass resources are also used to produce thermal energy in various industries and handicraft facilities such as the traditional brick, lime and pottery kilns, small sugar refiners etc.

Bagasse is used for combined heat and power (CHP) production in about 40 sugar mills in Vietnam for a long time. Electricity and steam produced is mainly used by the sugar mills in their production processes. It has been estimated that about two million tons of bagasse is used annually by sugar plants in the steam boilers to produce about 450 GWh electricity and 4 million tons of steam (Institute of Energy 2009).

Biomass Pellets Complete Plants in Vietnam

Compared with biomass resources, biomass pellets have higher density and combustion value. Vietnam has many plants producing biomass pellets for heating at home or in industrial boilers. As a professional manufacturer and supplier of biomass pellet mill, GEMCO has successfully set up two complete wood pellets production lines in Vietnam ( 32ton/h wood pellets plant & 6ton/h wood pellet line ). The pellets output capacity mainly depends on the number of ring die pellet mills. The 6 tons per hour pellet line contains 3 sets of pellet mills, while the 32tons per hour has 16 sets. Both two wood pellet lines have been performing well ever since they have been established, and have brought large benefits for the clients. What’s more, these two wood pellet lines also contribute to solving the local employment problems.

Vietnam has invested large sum of money on making full use of biomass energy. And we believe many more biomass resources will be made into pellets or briquettes or other high-density solid fuels.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!