Can we use biomass fuel in coal-fired boilers?

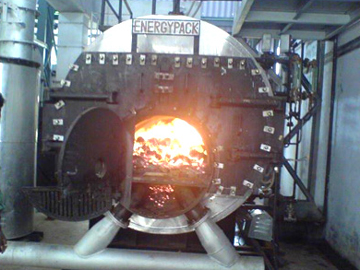

To solve air pollution, government in many places requires to install smoke purification system to the coal-fired boiler, or transform the coal-fired boilers into gas-fired or biomass-fired. Considering the transforming cost, biomass-fired boilers are the most economical. And biomass fuels have high heat value, low smoke or ash emission, and cost low. But do we have to replace new boilers? Can we transform coal-fired boilers to biomass boilers? Can we use biomass fuel directly in coal-fired boiler?

coal-fired boiler and biomass boiler

Can we use biomass fuel in coal-fired boilers directly?

Traditional boilers are designed for coals. Although some wood pellet fuels has higher heat value than coals, their burning efficiency is low in coal-fired boilers. Incomplete combustion of wood pellets will generate a lot of black smoke and ash, and cause large area of coking in the grates. Wood pellet fuels are light in weight, which will generate fly ash under the function of hot blast.

Biomass boilers are different from coal-fired boilers. The grate gaps of coal-fired boilers are too large for wood pellets. In biomass boilers, the wood pellets are gasified and fed by a hopper at a constant speed so that they can burn sufficiently. After gasification, the hearth is filled with high-heat flames with little smoke. If fed to the hearth manually and without gasification, wood pellets would generate a lot of smokes.

In conclusion, although wood pellets can burn in coal-fired boilers, the burning efficiency is rather low. It is a waste of wood pellet fuel and may cause damage to the coal-fired boiler. So we need to transform the coal-fried boilers.

How to transform coal-fired boiler to adapt to biomass fuel?

Both coal and wood pellets are solid fuel, suitable for chain-grate firing. Compared with coal, wood pellets has less fixed carbon content, but higher volatiles, coke and oxygen content. So wood pellets are easy to ignite, with short combustion period, and the cokes are hard to burn out.

Comparison between biomass fuel and coal

| Type |

Biomass fuel |

Coal |

|---|---|---|

| volume |

compressed volume, save space, easy to transport |

high volume, large storage space, high transportation cost |

| efficiency |

high burning efficiency, easy to burn out, little carbon residue |

high ignition point, hard to ignite, high volatiles |

| environment effect | no SO2 or P2O5 emission | generate SO2 and P2O5 and cause acid rain |

To adapt to the combustion characteristics of wood pellets, coal-fired boilers have 5 parts that need transforming, and 2 parts optional. The 5 required transformations includes the installing anti-incineration device, transforming the front arch(radiation arch), shorten the back arch(convection arch), adding secondary and tertiary air inlet, and installing high-temperature fan. The 2 optional transformations refers to upgrading the feeding method and dust collector.

As proved by hundreds of customer cases, by transforming these parts of a coal-fired boiler, it can improve the burning efficiency of wood pellets, solve the smoke emission and coking effectively. The transformed coal-fired boilers run well with both coals and wood pellets.

Use biomass boilers to replace coal-fired boilers

Although we can transform the coal-fried boiler to improve the heating efficiency, the transformation work requires much efforts and complicated technique. Without a professional engineer, you can not ensure you have done everything right. If you don't want to take time and risks, you can buy a professional biomass boiler, which can achieve the best combustion effect for biomass fuels.

Features of biomass boilers

- Biomass boilers features steady combustion, fast ignition, large flame, high heat efficiency, and stable operation conditions.

- Biomass boilers has different burning method from coals. The SO2, smoke and NOX emission are less than coals. The burn out rate is higher than coal, so the ash residue is little.

- As the ignition point of biomass fuel is far lower than coal, you can’t bank fire when you blowout the furnace temporarily. So the biomass boilers need operate continuously, and the biomass fuel consumption is higher than coal.

- When you have to stop the furnace under certain condition, you need to burn out the fuels on fire grates and clear up the slag, or the biomass fuels in the hopper may catch fire.

Notes on using biomass boilers

- Adjust the fuel supply of the screw feeder according to the actual fuel consumption.

- As long as the fuels haven’t burn out in the hearth, you cannot stop the draught fan.

- If the power cut suddenly, you must clear up the fuel in the hearth in time.

- Don’t feed biomass fuels when you have decided to stop the boiler.

- To stop the biomass boiler, you don’t need to bank fire. After the fuels on the grates burn out, you can stop the draught fan.

- As the biomass fuel slag contains alkalis like silicon, chlorine, potassium, and sodium, the melting point it low. They are easy to coke in the hearth and deposit on the heating surface. So you need to clean the hearth and fire tube regularly.

*Gemco is a professional biomass fuel equipment manufacturer and supplier. We supply flat die and ring die pellet machine that make various biomass materials into wood pellets. If you have demands or any questions, please leave us a message in the form below.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!